At the outset, we need to find a suitable auto repair shop specializing in hybrid vehicle repairs, and also conduct a comprehensive analysis of the entire vehicle. The most crucial information we need to obtain is the post-accident condition and potential repair costs.

- Find the right auto repair shop.

- Restore 12V voltage to all controllers.

- Diagnose all controllers through scanning with diagnostic software.

- Inspect the hybrid battery.

- Consider potential repair options, including even hybrid battery regeneration.

After an accident, it’s possible to diagnose the car using diagnostic software, which will initially indicate which components are damaged. We will then be able to check the hybrid battery. It’s also essential to repair the 12V terminal detonated after the accident.

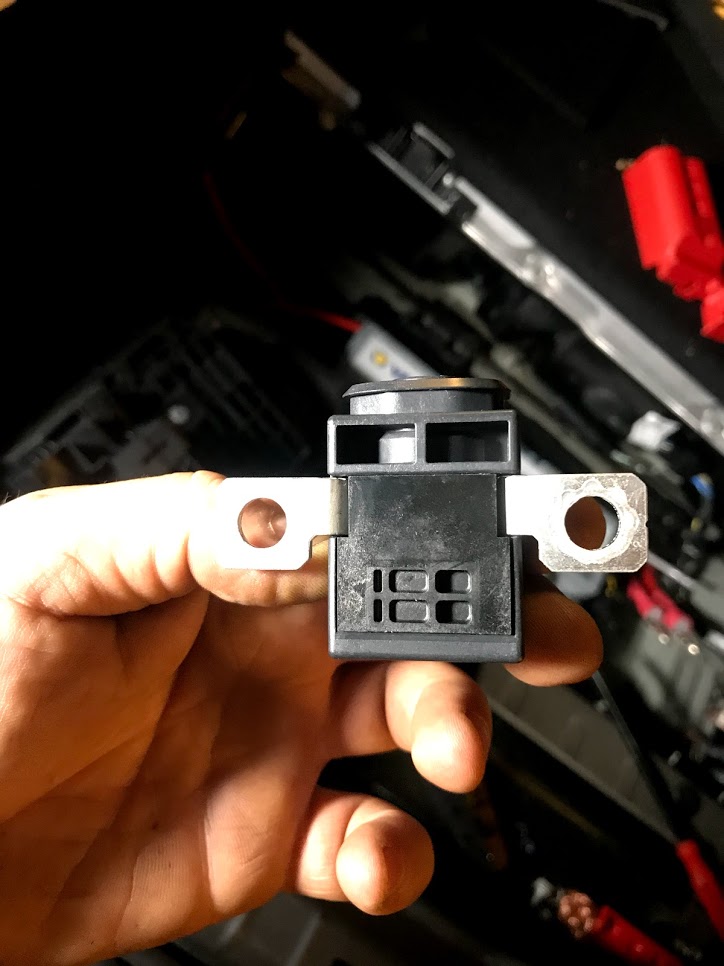

Pyrotechnic charges placed on the positive battery terminal, as well as in the fuses, detonate after an accident. This occurs when the AirBag controller activates the airbags, seatbelt tensioners, and cuts off the 12V voltage. It becomes necessary to restore the damaged sheet metal part to restore voltage to all controllers, to diagnose the car, or even to charge the hybrid HV battery back to its nominal value. Temporarily, we can allow for a provisional connection. This is necessary to determine the technical condition of the hybrid vehicle. Only after these steps can we proceed to diagnose the vehicle.

Repairing the HV hybrid system after an accident is troublesome for mechanics, electricians, or panel beaters due to the numerous system safeguards. More and more often, damaged cars with multiple mechanical and electrical faults are encountered. Finding the right workshop with experience in this area of repairs is very difficult and troublesome. However, it is essential in assessing HV system damage, as repairs may turn out to be more costly than the value of the vehicle itself…

Protection of 12V after detonation.

(EME) Electrical Machine Electronics

What is Electrical Machine Electronics (EME)?

This device has several applications in its operation and is a crucial component of the HV system, alongside the battery. Electrical Machine Electronics replaces the alternator in the internal combustion engine. Any damage to this component qualifies for the replacement of the entire EME unit. This is because it is a coded part that is not repairable, and the price can reach up to 40,000 PLN.

(KLE) Convenience Charging Electronics

Comfort charging electronics controller KLE, also known as the AC/DC voltage converter, can be damaged in case of using an inappropriate charger or short circuit in the electrical installation. This component is not as expensive as the EME. However, in the event of needing replacement with a new one, the costs can amount to up to 10,000 PLN.

Hybrid batteries

Inspection of the hybrid battery after an accident is essential to check the condition of all cells. Then, if the test turns out well, it is necessary to charge all battery cells to their nominal value during the car repair. If we fail to do this and leave the battery at a minimum charge level, it can result in irreversible degradation of all cells, and replacing this component can cost up to 50,000 PLN.

After completing repairs on a hybrid vehicle following an accident, it may turn out that the hybrid system is not functioning properly (lack of charging the 12V battery). We may also notice additional faults during the assembly of such a vehicle. Despite the fact that the internal combustion engine is operating correctly, we are unable to charge the onboard batteries to 14.8V. It is worth conducting a full vehicle diagnostic before starting any repairs to ensure that all faults in the car do not exceed its value.

| Error Code | Explanation |

|---|---|

| 930994 | Battery safety terminal: Excessive resistance |

| 93099A | Safety shut-off of additional starting device due to safety reasons: Excessive resistance |

| 21F148 | High-voltage interlock loop control: Interruption |

| 21F1F6 | High-voltage battery, disconnecting contactors: Disconnecting pop-up error |

| 21F10C | High-voltage battery module: Accident signal, serious event recognized |

| 21A005 | Emergency mode manager information: Torque reduction, EME request, level 3 |

| 21A11A | Emergency mode manager information: MSA deactivation, called for internal combustion engine switch, EME request |

| 21A50A | Starter system, starter with pinion: Multiple exceeding of time |

| 218215 | Additional starting device, additional battery charger: Charging interruption due to excessive temperature or wire interruption |

| 806034 | Fuel tank cut-off valve or pressurized tank system: Protected mode |

| 0316D7 | High-voltage battery module: Category 7 error, immediate disconnecting contactors |

| 22281C | High-voltage power management: High-voltage system not activated despite request |

| 222834 | Charging management system: Check-Control 804 message, charging impossible |

| 0316D1 | High-voltage battery module: Category 1 error |

| 0317C5 | High-voltage protection function: Disconnection due to clamp signal 30C |

| 222812 | High-voltage power management: High-voltage system shutdown due to severe collision |

| 2232A4 | High-voltage protection function: Disconnection due to hardware signal |

| D78C00 | Additional starting device, intelligent sensor (IBS) of additional battery: LIN data bus, no communication |

| 801A4B | SINE: Too low voltage recognized |

| E71459 | Signal (torque limitation of AC compressor crankshaft, 0x1B9) incorrect, transmitter DME/DEE/EDME |

| 1F1B54 | Onboard network voltage, power supply voltage: Malfunction |

| 0316D6 | High-voltage battery module: Category 6 error, contactors opening command |

| 0317C4 | Electric machine controller, high-voltage interlock loop control, short circuit signal |

| 0317D6 | Electric machine controller, high-voltage interlock loop control, short circuit signal |

| 0317D7 | Electric machine controller, high-voltage interlock loop control, short circuit signal |

| 0316D7 | High-voltage battery module: Category 7 error, immediate opening |

| 222816 | High-voltage power management: High-voltage interlock loop control |

| 22281C | High-voltage power management: High-voltage system not activated |

| 2228C8 | Additional starting device, additional battery: |

| 0316D1 | High-voltage battery module: Category 1 error |

| 0317C5 | High-voltage protection function: Disconnection due to clamp signal |

| 222812 | High-voltage power management: High-voltage system shutdown |

| 2232A4 | High-voltage protection function: Disconnection due to signal |

| 222819 | High-voltage power management: Insufficient onboard network supply |