Regeneration of HV Hybrid Vehicle Batteries

When a customer approaches our auto repair shop with an error on the dashboard of their electric or hybrid car, our professionals start with diagnostics to determine which system and then which component is causing the issue. They do this by connecting the car to a computer with the original software from the car manufacturer. Most errors and problems are caused by HV hybrid vehicle battery or an inverter malfunction.

After the initial diagnostics, the customer gets a printout with the diagnostic report of his car. The diagnostic report of an electric or hybrid car contains all the errors and warnings from all the vehicle’s systems including the battery. This way, the customer is fully informed about the mechanical and electrical condition of his electric or hybrid vehicle and is aware of exactly which part has failed.

We also present the customer with all the options available to them. In most cases, there are three. First one is to replace faulty battery with a new original battery designed for the brand and model of the specific vehicle. The second option, is to replace it with a battery from another manufacturer. It should be noted that, as of today, the availability and selection of battery replacements are very small. The third option, which is unavailable at most other workshops, service centers and even authorized dealers, is the regeneration of a battery.

Our auto mechanics and electricians are experienced and certified professionals, as proven by the numerous training courses received at respected training centers such as Bosch Training Center, Excellence, Achievement & Learning Limited and Auto Elektro Academy.

Hybdrid Vehicle Battery – Examples of repair and regeneration

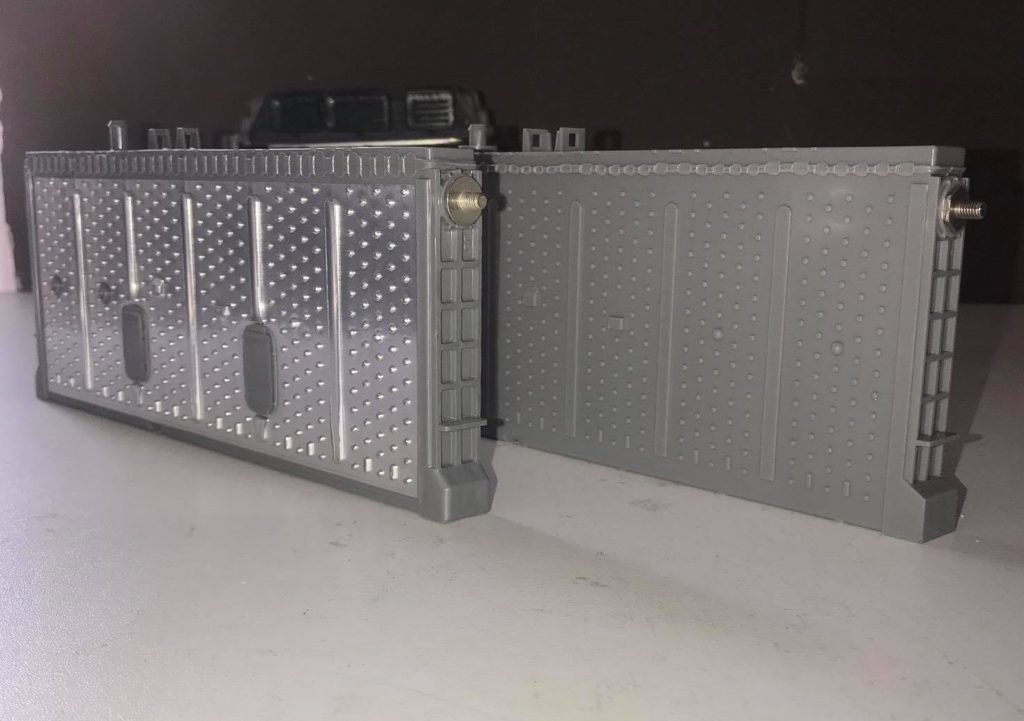

Inverter/converter during regeneration performed by one of our auto electricians. Inverter/converter also known as voltage converter, and sometimes referred to as a power converter. Is is an electrical device that changes direct current into alternating current and alternating current into direct current. It has a very important function in hybrid and electric vehicle power systems.

Faulty HV (High Voltage) battery cell replacement is one of the steps in the full regeneration of hybrid and electric batteries in our repair shop.

Hybdrid Vehicle Battery – Examples of repair and regeneration

Available options when dealing with a faulty battery:

- Replacing a hybrid battery with a new battery from the car manufacturer.

- Replacement of the battery with a battery from another manufacturer/car brand.

- Regeneration of a battery is possible in both electric and hybrid vehicles

While choosing the regeneration over buying a new battery it is important to take these two things into consideration. First of all if the battery already has a certain age around 7/8 years or more it should not be regenerated and should be replaced with a new one. Also, it is possible to replace the battery and its cells with a used electric battery, but only if the replacement parts do not have a mileage of more than 50,000 kilometers.

Down below you can watch a video showing how the regeneration of hybrid batteries takes place, using a battery from Toyota Prius:

Most hybrid car manufacturers guarantee battery life expectancy equal to the estimated life of the car, which is about 150,000 kilometers, sometimes even 200,000 kilometers or more, so in most cases, that translates into 10 years.

If our customer chooses the option of regeneration/repair of battery, our mechanics will remove it from the customer’s car, make a diagnosis of the battery itself and all the cells in it. These are either lithium-ion (Li-ion) or nickel-metal-hydride (NiMH) cells. After the diagnosis of the hybrid battery, our service personnel, will fully recondition the battery for the customer, test the battery and install it back in the vehicle.

What is a battery reconditioning? Should such a procedure even take place? What does the term really mean? How does such HV hybrid battery reconditioning proceed?

Surfing on the Internet, one can come across various articles describing the process of regeneration of any battery. Unfortunately, these materials are usually not written by experts in this field, but rather by people who have little to do with the subject and let their imagination run wild. These descriptions are not supported by knowledge in the field of electromechanics or experience gained in an auto-electrician’s repair shop. They are often written according to the rules of SEO by so-called copywriters, only for gaining clicks and views. They are meant to attract attention and increase the amount of content on the site, rather than to give an honest account of the process, which is still a secret knowledge. Professionals are reluctant to share news from such a hermetic professional environment. In the meantime, we will make an exception, and as an electrician and electronics engineers, we will reveal a corner of the secret to you. We aim to correct and organize the scraps of knowledge that can be found on the Internet.

Self-proclaimed specialists declare that the treatments they can subject batteries to are: cell desulfurization, replacement, cleaning, reconditioning. Next to these items are assurances of the highest level of performance, which can further put your guard down. However, you have to ask yourself: why isn’t the service doing this? Why is there no company on the market that specializes in this? After all, we know many good brands, so Toyota, BMW or Mercedes would have had their own service, component remanufacturing companies for their electric and hybrid models.

The remainder of this post will aim to introduce the concept of regeneration and address concerns about this topic. Let’s start with the fact, that in some cases regeneration can be undertaken and in others a more costly replacement is necessary. As we know, batteries and rechargeable batteries of all kinds are mostly lithium-ion or nickel-metal-hydride and usually last longer than their stated suggested life. So that, they can serve so long and reliably, certain standards of charging, discharging, temperature and battery storage must be maintained. Lack of performance of a common 12 V battery after 3-5 years inevitably leads to its replacement. A similar situation, can be encountered not in an auto repair shop but in a phone service, when it is necessary to purchase and install a new battery in the phone caused by its frequent charging, undercharging to full battery and discharging. Lack of awareness of these factors inevitably leads to battery degradation, which is irreversible at such a stage.

Hybrid vehicle batteries, are nothing different from normal batteries, except that it is a set of cells arranged in sectors, which are watched over by a battery controller. Its task is to receive information about the battery’s charging status and resistance. The received information goes to the converter/inverter. The controller sends data when it should be charged, at what power and how much energy it can give off at any given time. The most common cause of battery failure in an HV system is the weakest cell. Since every battery package, without exception, is just made up of a dozen cells joined together. No cell is the same as its neighboring cells or those at the ends of the battery. During the production of such a battery pack, the battery’s capacity, internal resistance, ability and power to release electricity from itself are all checked with great accuracy. Each cell of a battery pack will put up any resistance during charging or discharging. The excessive instantaneous speed achieved by a hybrid car will rapidly extract the full power from such battery, from all its energy cells, which will further raise their temperature. The longer a hybrid car user wants to feel like a racing driver and treats the car like a Formula 1 car, the faster his battery will degrade. Simply put, at some point the weakest cell will not recharge. It will be the most inappropriate moment, but this is not the rules of mechanics or electrics, but simple human bad luck. I would add, that the rest of the cells will not work then either. Such a cell may also be overcharged and as a result it will be degraded in the eyes of a battery controller. To illustrate the problem, let’s assume that all cells have 8 volts and this one cell has 7 volts, 6.5 v or even 5. This results in an error signaled by the system and failure of the hybrid battery system. The diagnostician sees a system error titled “replace the battery” . The message says we should replace the whole battery, because the system does not provide for regeneration and sees the solution to the problem only in its replacement.

As an independent car repair shop, we do a thorough verification in cases, where the battery is fairly new and little used. Then we boldly propose to our customer to regenerate the battery, by which we mean to replace the cell/cells in question. There are also cases of permanent damage to all cells through improper use for 5-10 years. Then all the cells would have to be replaced. Full regeneration is then rather impossible. It still depends on the model. Several factors contribute to this. Leaving the car with the battery completely discharged or charging it to the end and leaving it damages the battery. The damage is irreversible and represents degradation of that battery.

However, sometimes it happens that the battery can actually still be saved by undergoing regeneration by verifying the cells, replacing them with used ones or replacing them with others. To carry out this process, you need top-of-the-line equipment. Such equipment diagnoses the technical condition by charging, discharging the battery and checking the internal resistance under load. Once this is done and the right working cells are selected, they can be arranged in the correct order by their power. Any minimum cool down of one of the sectors will lead to an error and the battery controller by incorrect volts and resistance values.

Some battery regenerating companies form and start business based on the belief that it only takes one cell for such battery to still perform well up to two years. As a result of such business, the customer pays a price equal to half of a new battery and the car is left with a battery that is damaged even more. If awareness of the care you need to take of a battery was greater, and new owners were informed about it by the car dealer, fewer batteries would be used up so quickly. It’s not indifferent to the environment either. The engineer that created the battery software inputs the information and sets the limitations of the particular cell. This data is given to him by a machine, which is used to test the cell in question, and he selects, for example 30 identical pieces that will fall within the same parameters (up to how many volts it can be charged, discharged and how much resistance there can be in the load, as well as the maximum temperature inside). Any deviation from this data in the battery will report an error, which the service will likely read as a signal to replace the entire battery including the controller. The vehicle owner will continue to remain in the dark. Only an independent service like ours, which has the needed conditions, remanufactures the components and has a specific devices is able to accurately diagnose the battery. The customer is given a printout with estimated efficiency of the battery and parameters such as the internal capacity of a given sector, the marginal value of charge, discharge, internal resistance and the temperature at the load of a given cell. It is unthinkable to me that any service would replace used cells, in a used battery with new once. But unfortunately, you can come across this practice and it can waste you a lot of money

Hybrids have been getting worse and worse on the market, because they are now on the road for longer and longer. Manufacturers are learning from their mistakes how to create better batteries and how to make them more efficient,for example by cooling them with air conditioning. Because of the modern approach, batteries are stored in aluminum containers. The problem is that it is common for a car to show up at the repair shop after an accident with a state of charge of 30-40% during a bump. It is left to be repaired, but most repair shops only take care of an external issues. Then, there often is a moment when you start the car, which is discharged and there is no possibility of charging. The safest value of state of charge is about 50%, it is worthwhile in such cases to go to a specialist first, who will be able to obtain it. He will also store it in suitable conditions until the hv system is repaired.

We also offer our customers the option of repairing hybrids by remanufacturing hybrid batteries with postal or courier shipping. The customer can send us his faulty electric or hybrid battery and we will fully remanufacture the customer’s hybrid battery and send it to the address indicated by the customer throughout Poland, at the request of our customers. We can also send the repaired battery abroad.

Hybrid Battery Regeneration – Price

Of the examples of options given above, the most expensive option is to replace an electric or hybrid battery with a new one. If the car is not too old and there are not too many kilometers on the meter, the cheapest option is usually battery regeneration – the price of a hybrid battery regeneration is much lower than replacing the entire battery. Replacing a new battery is a cost of several thousand zlotys. The average price of a new hybrid battery is about 18,000 PLN. The price of regeneration of hybrid batteries is in the range of 3,000 to 8,000 PLN – it is much lower than replacing an electric or hybrid battery.

Most Popular Services In Our Car Workshop.

Our customers write, call and come to our garage in Warsaw for many reasons. The most popular issues for our clients include:

1. Hybrid battery regeneration.

2.Hybrid battery repair.

3.Hybrid car repair.

4.Repair of electric cars.

5.Converting the car to a hybrid.

6.Conversion of combustion car to electric.

7.Motor diagnostics.

8.Electric car service.

9.PHEV – plug-in hybrid electric vehicle, it is a plug-in hybrid car, i.e. a hybrid vehicle that the owner can charge directly from the electrical outlet in his own apartment or garage.

Hybrids and Electrics – Repair and Service of Hybrid and Electric Cars.

The most frequently serviced vehicle brands are:

1.BMW

2.MERCEDES

3.KIA

4.TOYOTA PRIUS

5.LEXUS

6.PORSCHE

7.PEUGEOT

8.TESLA

Although we are mostly visited by car owners of the brands and models listed above, our trained and certified auto-electromechanics are able to diagnose and repair almost all (if not all) makes and models of electric and hybrid cars – hence the name of our website: Hybrids & Electrics

Automotive Workshop Warsaw – Service and Repair of Hybrids and Electricians.

If you are interested in one or more of these services, please contact us at

511 671 050 or by e-mail – you can send us an e-mail at dyd.renovations@gmail.com or visit us at our garage, hybrid and electrical service at Czapelska 24a Street, Warsaw and Grochowska 301/305, 03-842 Warsaw.

We invite you to visit our Car Workshop!

If you need help finding our location, please use the map with our location on Google below.