Need help repairing your BMW battery? Contact us

We have the best bmw battery tester on the market, plus full-skilled workers who have been engaged in bmw car battery regeneration for years. We invite you to visit us HybrydyElektryki Warszawa.

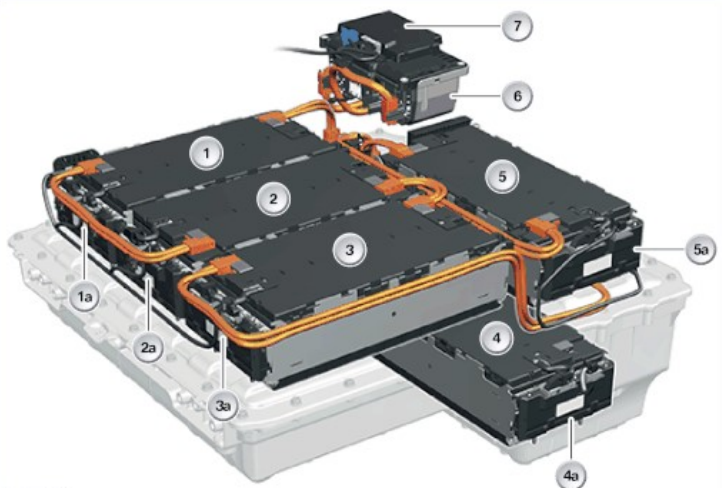

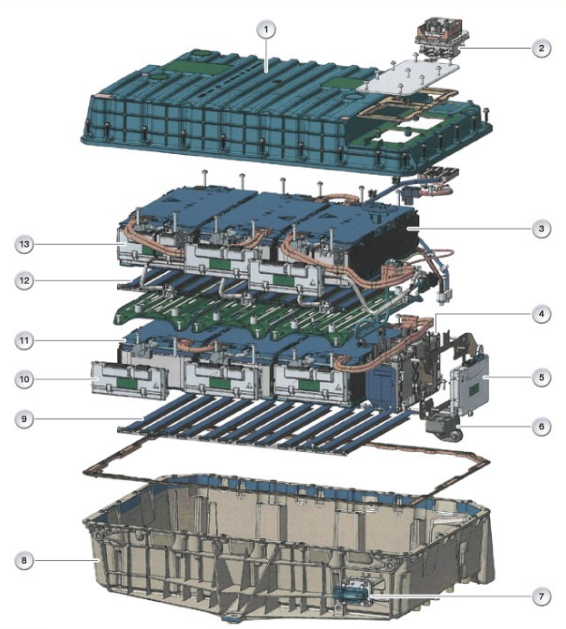

The HV battery assemblies in hybrid and electric vehicles represent an electrical system that must be inspected after repair or transport for restarting. This inspection is carried out to ensure that the battery can operate safely and that it does not pose any threads.

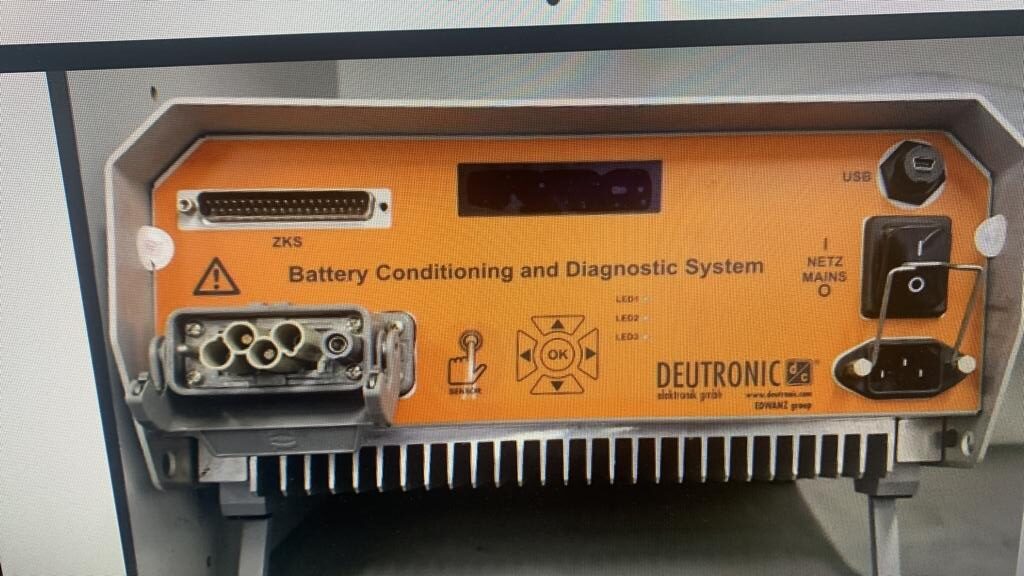

In order to start the vehicle after unlocking the battery the ISTA diagnostic program has to be used – it is a program dedicated for BMW vehicles. The vehicle is connected to the program through the OBD input. Unlocking the battery is possible only after entering the EOS code. The code can be obtained thanks to the EOS tester. This device is responsible for carrying out a battery test, examining its most important parameters. A positive test result makes it possible to generate a code, which must be entered during the procedure for unlocking the high-voltage battery system. The EOS test takes about 30 minutes.

Parameters checked by the EOS tester:

1. errors/warnings

2. error codes before and after the test

The leakage test of the high-voltage battery unit is allowed only under the following preconditions:

• The high-voltage battery unit and the components needed for repair are brought to the

correct temperature

• The high-voltage battery unit and the mentioned components are at a constant temperature

for at least 12 hours

• The minimum permissible temperature is 12 °C

• The maximum permissible temperature is 26 °C.

• The HV battery unit must not be exposed to heat radiation (e.g., sun or heating) or cold

radiation (e.g., air conditioning) during operation.

Failure to meet these environmental conditions may lead to incorrect test results and is not

acceptable.

4. checking if short circuit occurs

5. voltage at terminals

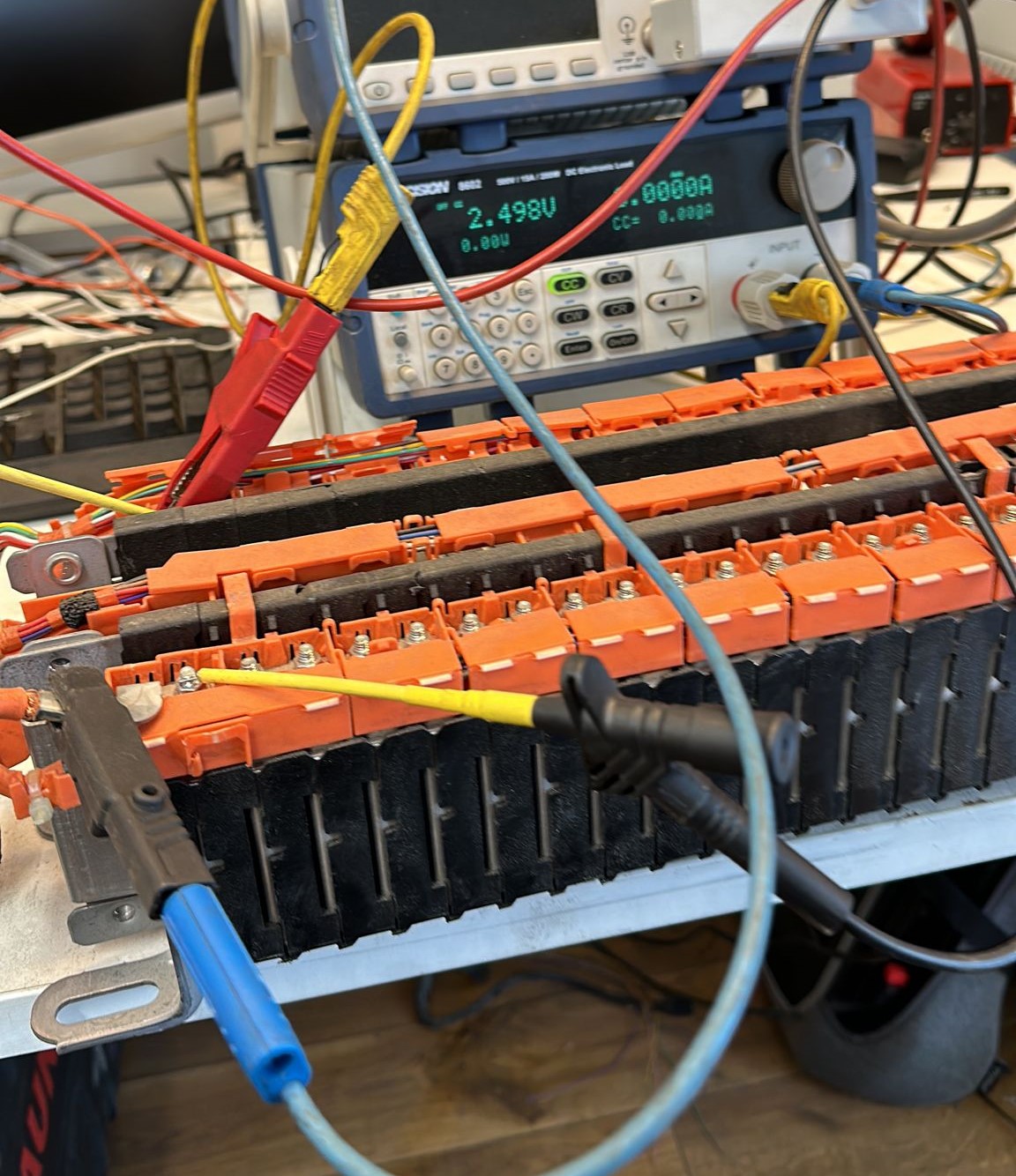

6. voltage on individual modules

7. state of charge of the battery and its individual modules (it is important to keep their state of charge at the same level or with a minimum difference specified by the manufacturer)

8. the minimum and maximum value of the state of charge and voltage of the cells (deviation between cells)

9. insulation resistance

10. HV insulation test

11. battery temperature

A device consisting of three relays, having an ammeter and voltmeter, which sends a control voltage

before starting to transmit voltage to the inverter ( in case of error or exceeding the permissible

value, the main contactor will not be closed), this function is called precharging.

Correct functioning of each component of the battery assembly and compliance of the parameters

with the applicable standards provided by the manufacturer will achieve a positive test result.

When working in the vicinity of high-voltage components (marked with warning stickers and/or

orange coating), disconnect the high-voltage system from the power supply and protect it from

damage. Before starting work, make sure that the measuring equipment and connecting cables are in

perfect condition.

Make sure that all precautions are taken and that local regulations are followed. Also observe the

test setup throughout the test so that you can react in case of any disturbances.

Repairs to the high-voltage battery unit must only be performed by specially trained and authorized

personnel.